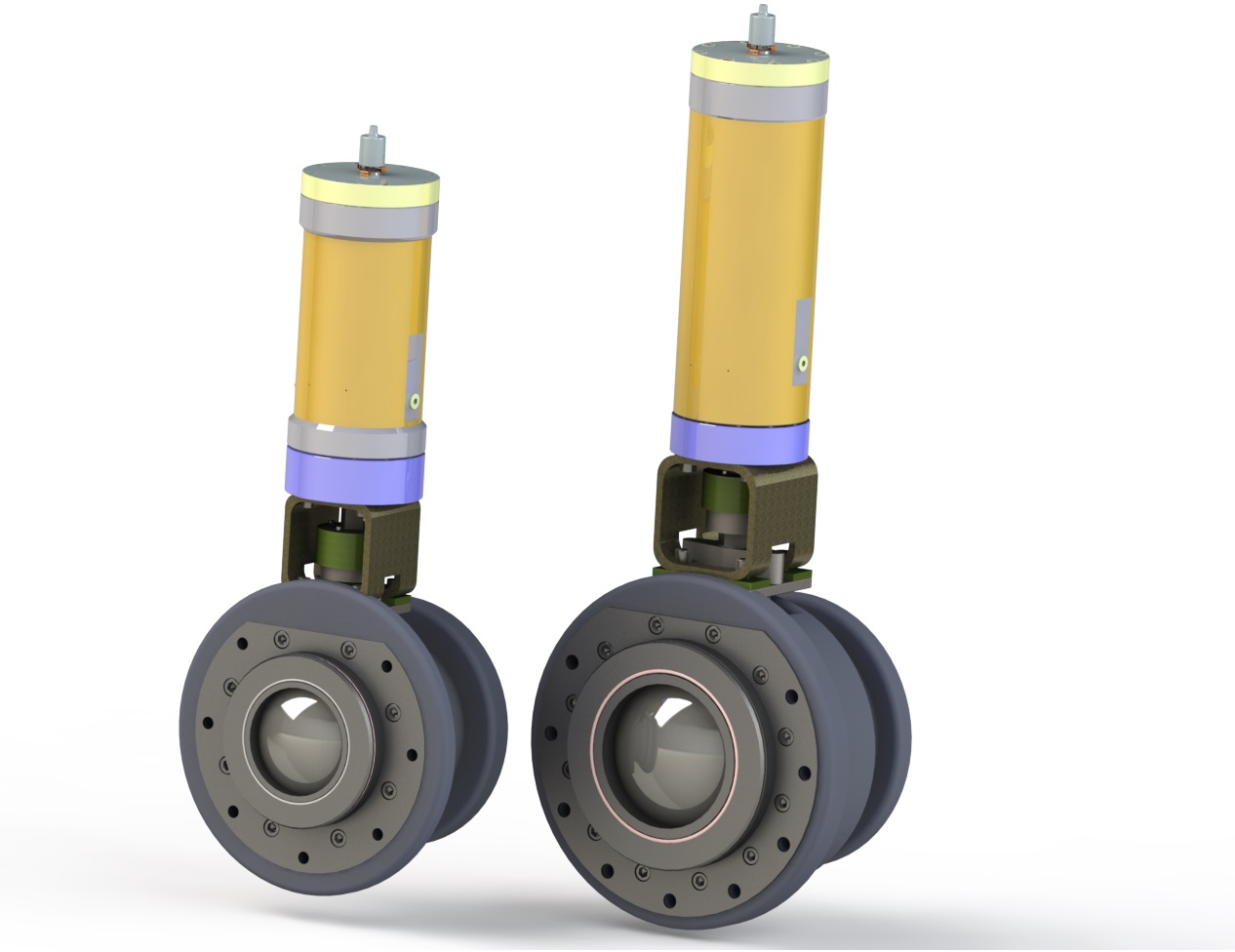

Heat-resistant floor-drain ball valve

The von Scheven company secures diaper production in Southern Europe

Engineers of Rudolf von Scheven GmbH, jointly with a German mechanical engineering company, have developed individual floor-drain ball valves. The primary objective of the co-operation was to permanently secure the mixing process of the adhesive for the diaper producer by means of a reliable ball valve. The development team, who consisted of experts from both companies, considered the most varied performance-influencing factors in the planning stage.

One of the big challenges was to enable the permanent flow-through of liquid adhesive at an operating temperature of +200°C. The engineers have developed a tailor-made heating jacket which prevents the temperature from lowering. The jacket covers the floor-drain ball valve completely and protects the valve in the vertically-assembled state against outside temperatures. In this way it is prevented that the medium cools down and hardens due to that. A minimised dead space between the ball cock and the mixing tank additionally guarantees a complete mixing process.

The floor-drain ball valves were implemented in nominal diameter 150 and 200. Housings and flanges consist of stainless steel. Likewise specially-produced hydraulic drives activate the valves. These are provided with a spring return and also resist high temperatures. Heat bridges of laminated fabric additionally guarantee a low thermal conductivity between drive and ball valve.